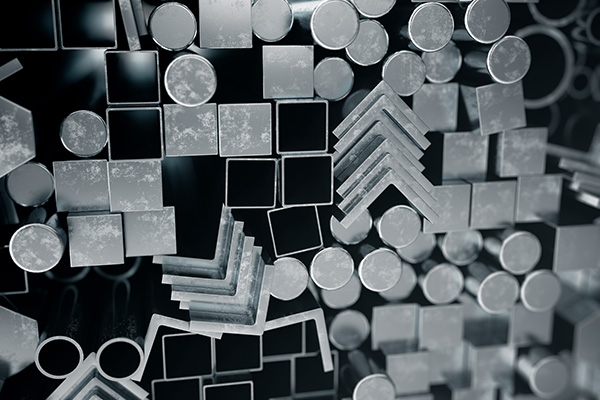

Steel – and alloy of carbon and iron – is one of the most widely used metals in the world. It has excellent properties for a practical metal. It is heat and cold-resistant, does not shed matter, and can be treated easily with zinc so that it does not rust. Therefore, it can be used for a number of things. Here are four innovative uses of steel.

Baling Wire

Recycling is a huge industry and incredibly important for the welfare of the planet that we all live upon. A whole host of technological innovations have been developed in order to make recycling more efficient. Steel plays a huge part in the recycling industry.

Cardboard is one of the most widely recycled materials. In the United States, 67.4 million tons of paper and cardboard were recycled in 2018 alone. Cardboard recycling is usually stored in bales. 12 Gauge steel wire is the preferred material used for tying these huge cubes of cardboard together. Because steel is both tough and flexible, it is perfect for winding into extremely strong wires.

Musical Instrument Strings And Wires

Pianos and guitars used to be strung with natural fibers. These fibers were typically made with animal guts. Although they made a beautiful sound, they were incredibly labor-intensive to make and would break easily. Wound steel is now the almost universal string-making material. Wound steel vibrates sweetly when plucked by a hand or struck by a piano hammer. Steel strings have also lent themselves to several genres of music. Mississippi delta blues, for instance, would not sound the same without the distinctive sound of a bottle top being slid across the steel strings of a guitar. The small ridges in steel strings caused by the winding process allow lateral motion to stimulate vibration – leading to the distinct slide guitar sound.

Brewing And Food Processing

Steel has replaced wood as the most commonly used material in the production of food processing and brewing vessels. This is because steel – in its stainless form – does not emit oxidized matter into products that would cause changes in the way a finished food or drink would taste.

Railway Tracks

Modern railway tracks – unlike their 19th and 20th Century ancestors – are made of continuously welded steel. Older train tracks are made of individual lengths of cast iron that are connected together using fishplates. This was a reasonable way of producing tracks, but it was found that they were subjected to lots of damage from warping. As temperatures rose and fell, the iron rails would bend, which in turn compromised the integrity of the fishplates. This constant warping and loss of integrity meant that train tracks had to be frequently changed in order to keep them safe.

Final Words

Modern tracks, on the other hand, use high-quality steel that is continuously welded together. Steel is incredibly good at flexing without losing its properties. It can withstand high temperatures and very low temperatures without being at risk of cracking. It reacts well enough to welding and so no fishplates are needed to hold lengths of track together.